M.H Ramezannia

CV site

Thermal modelling of transfer-bonded thin-film gallium arsenide laser diode

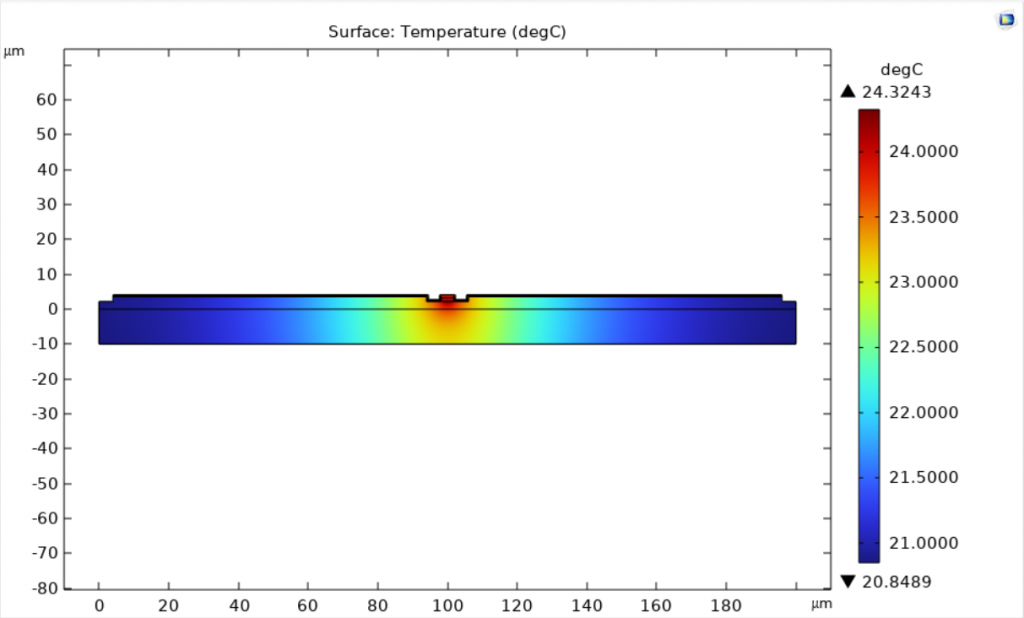

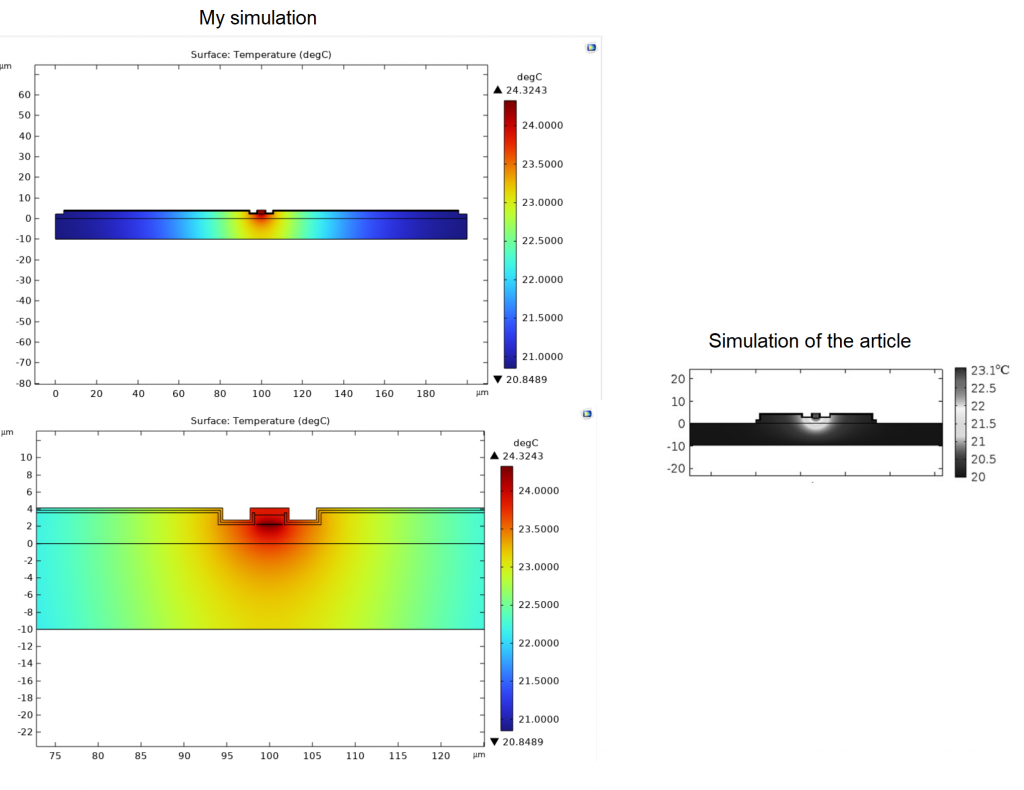

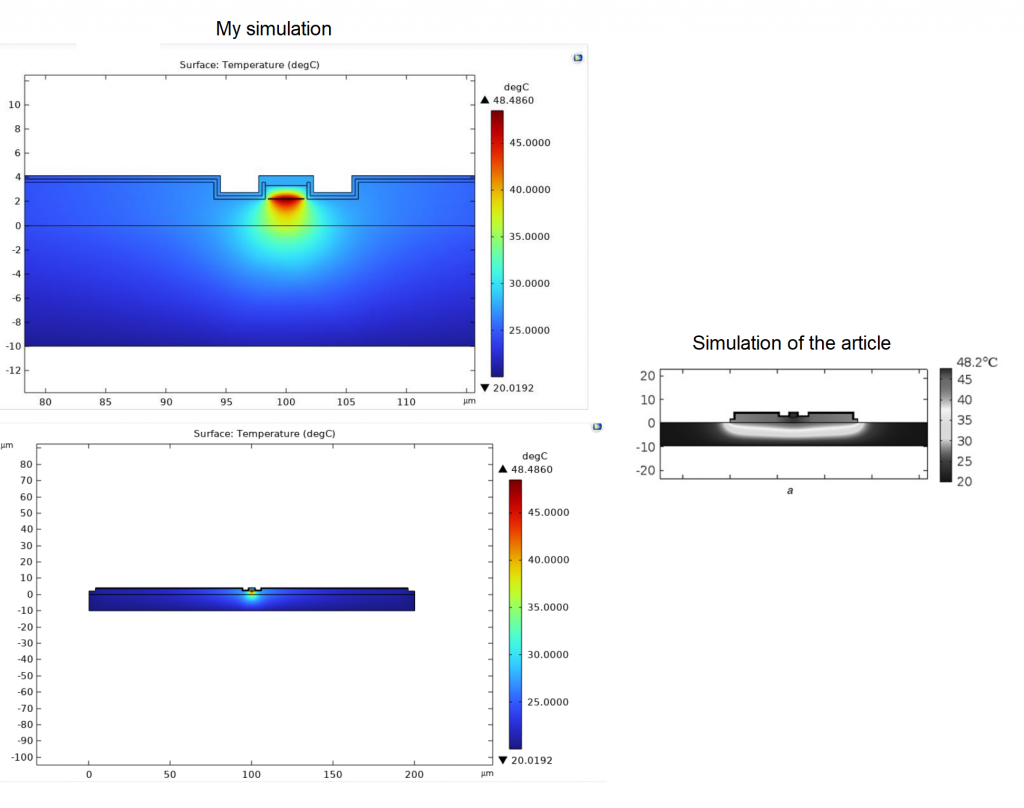

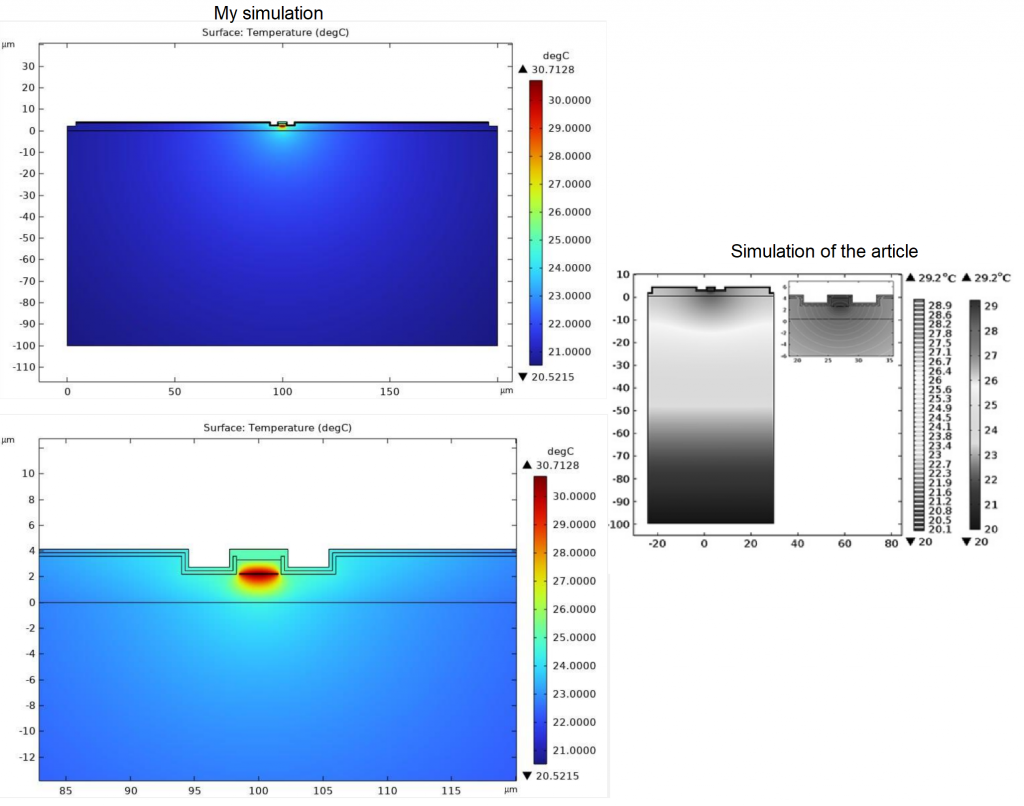

In one of my university projects, I attempted to simulate thermal modeling using COMSOL. To do so, I selected an essay titled “Thermal modelling of transfer-bonded thin-film gallium arsenide laser diode” with doi: 10.1049/iet-opt.2015.0061. However, the information provided in the article was insufficient, and I had to make assumptions for certain values to ensure that our simulation was similar to the article.

Despite the lack of detailed information in the essay, I was able to successfully carry out the project by making educated assumptions. By doing so, I was able to gain a better understanding of thermal modeling and its applications in various fields. Overall, this project was a valuable learning experience for me, and it helped me develop my skills in simulation and data analysis.

Introduction

The article titled “Thermal modelling of transfer-bonded thin-film gallium arsenide laser diode” focuses on simulating the two-dimensional temperature distribution of a thin layer of gallium arsenide (GaAs) using COMSOL software. The simulation involves connecting the GaAs layer to substrates with different thermal conductivity values, and comparing the thermal resistance with a simple steady state analytical expression. The study also investigates the effects of various factors such as laser cavity length, dielectric passivation layer thickness, contact metal layer thickness, and submount material on reducing laser thermal resistance.

Through the simulations, the study highlights the importance of reducing the thickness of the gallium arsenide substrate, particularly for short hole lengths. The findings suggest that reducing the substrate thickness can significantly reduce laser thermal resistance and improve the performance of the laser diode. Overall, the study provides valuable insights into thermal modeling and its applications in optimizing the design and performance of laser diodes.

Result

The article presents a simulation of the temperature distribution of a laser diode with and without subduction of the gallium arsenide substrate. The simulation shows that for continuous operation at room temperature with a thermal load, the laser diode with a completely removed substrate has a lower joint temperature compared to the laser with a 100 µm thick substrate. The thermal resistance of the transfer laser is much lower than the reference laser, indicating that reducing the thickness of the gallium arsenide substrate can significantly reduce the thermal resistance.

The study highlights the importance of reducing the thickness of the gallium arsenide substrate in reducing thermal resistance and improving the performance of the laser diode. The findings suggest that the gallium arsenide substrate is the biggest contributor to the total thermal resistance, and reducing its thickness can greatly reduce thermal resistance. The simulation provides valuable insights into optimizing the design and performance of laser diodes by considering factors such as substrate thickness, laser cavity length, dielectric passivation layer thickness, contact metal layer thickness, and submount material.

The project files can be downloaded from here.

Description

University

May 21, 2023

In this post, I wrote about one of the projects I did during university.